AlN & AlScN Deposition Services

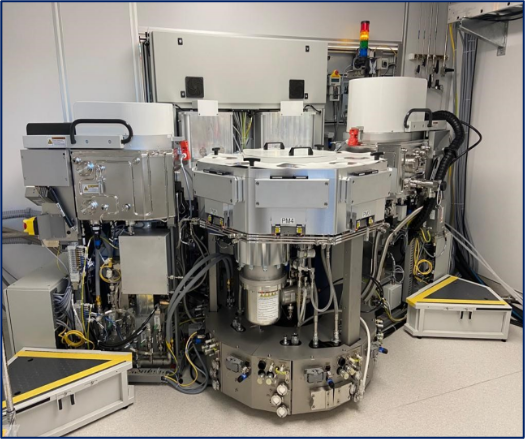

Access to advanced deposition facilities featuring the CLUSTERLINE® 200 system with comprehensive characterization capabilities.

• Co-Sputtering Chamber: In-Situ deposition of Ti, Pt, Al, Cr, AlN, and AlScN with composition control

• Single Target Chamber: High-throughput, high-uniformity AlN and AlScN deposition

• Sample Compatibility: Can accommodate samples from small chips up to 8" wafers

• Film Characterization: XRD for texture and crystallinity analysis, stress measurements, SEM/AFM for cross-sectional and surface analysis, thickness measurements, and particle counting

• Single Target Chamber: High-throughput, high-uniformity AlN and AlScN deposition

• Sample Compatibility: Can accommodate samples from small chips up to 8" wafers

• Film Characterization: XRD for texture and crystallinity analysis, stress measurements, SEM/AFM for cross-sectional and surface analysis, thickness measurements, and particle counting

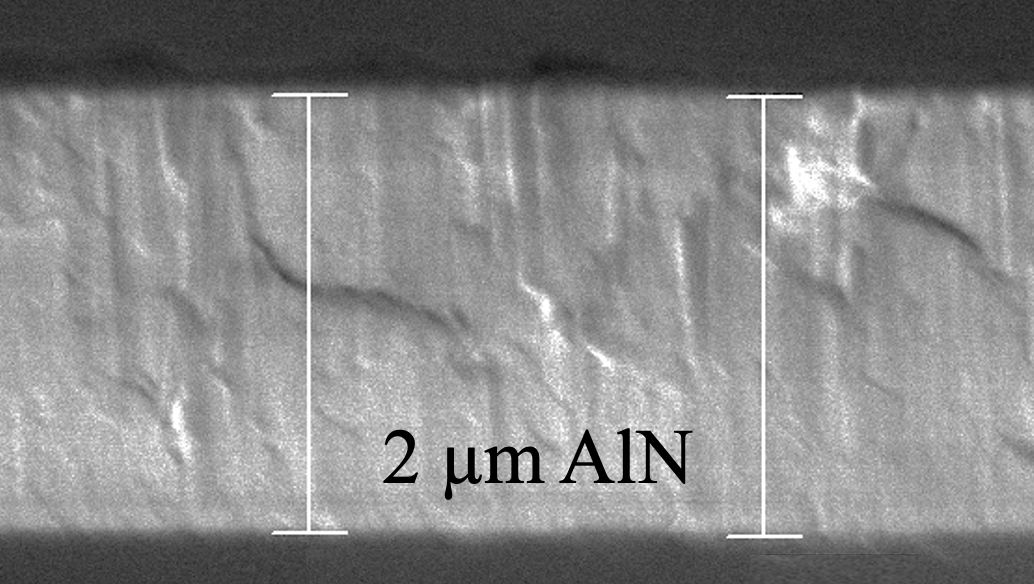

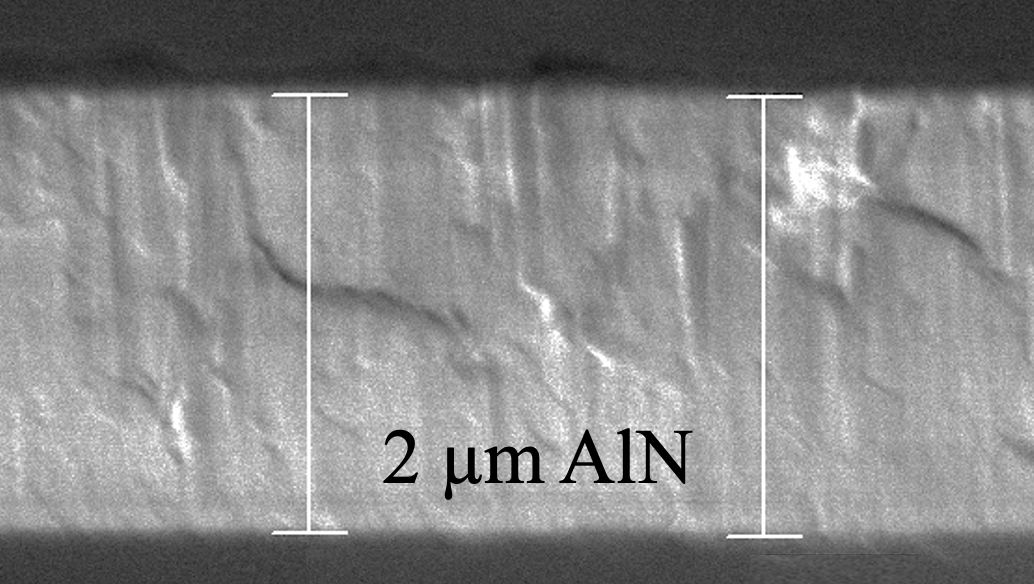

Cross-Sectional SEM

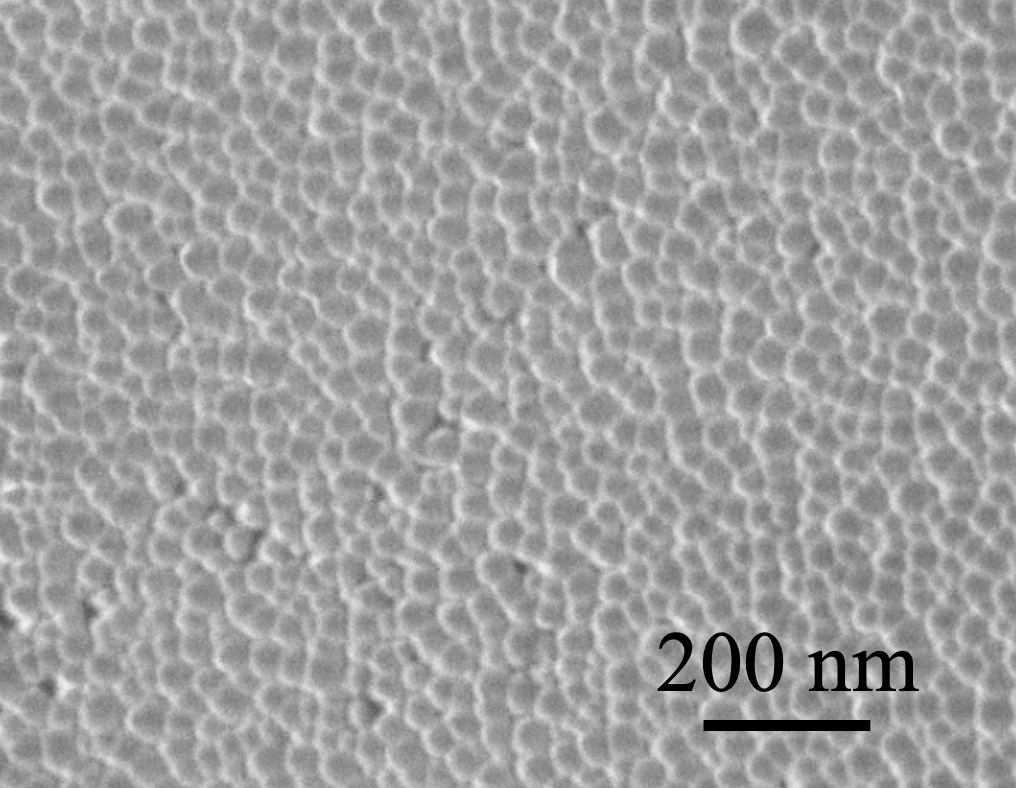

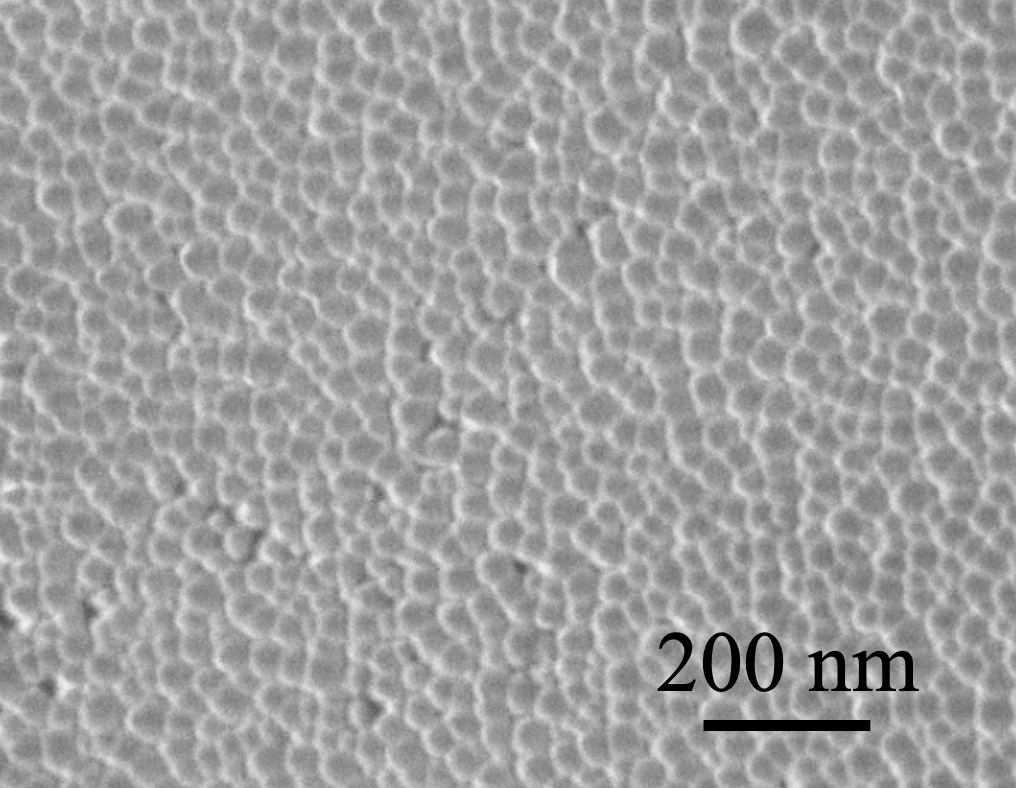

Top-View SEM

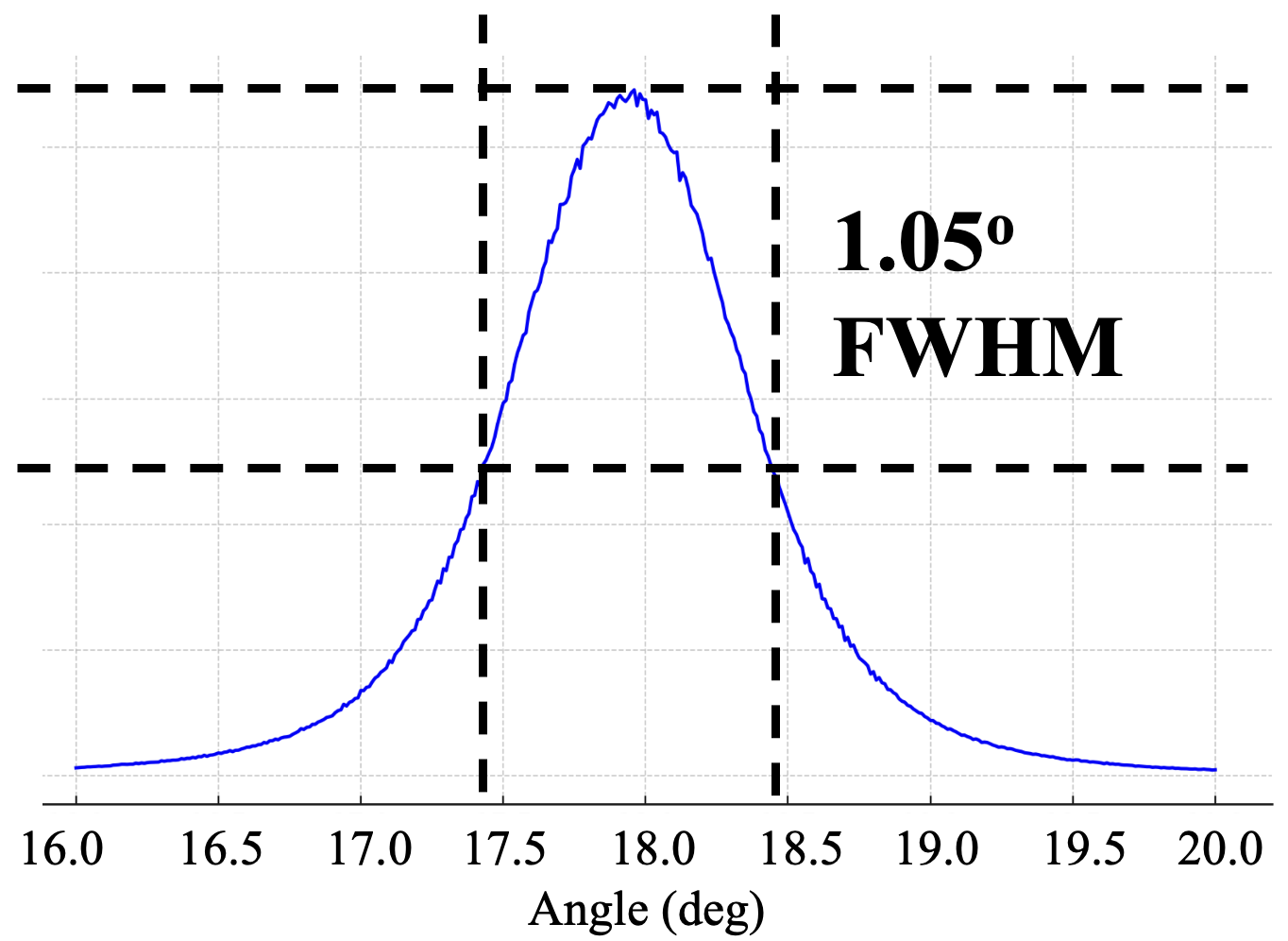

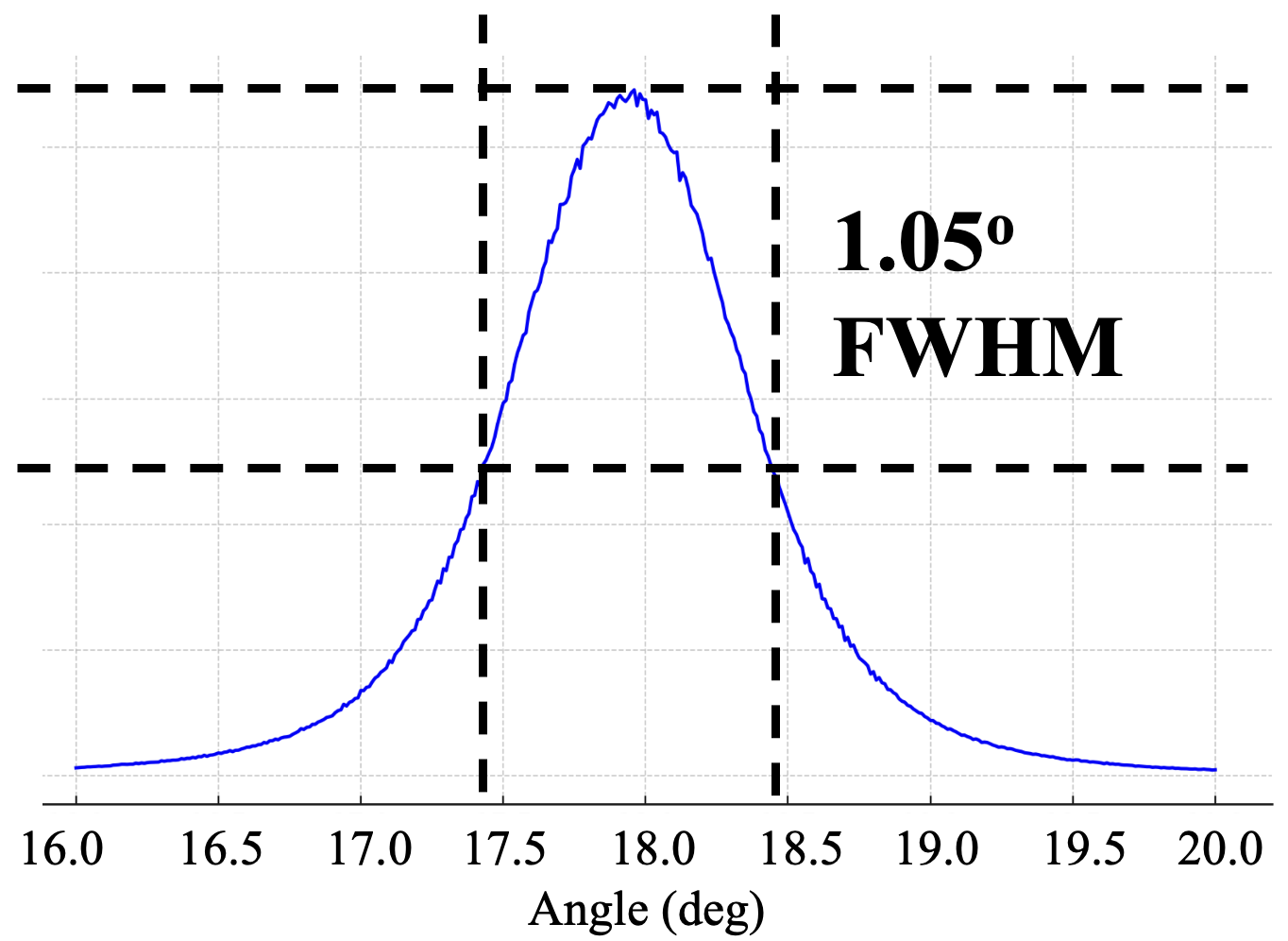

AlN Omega-Scan

Cross-Sectional SEM

Top-View SEM

AlN Omega-Scan

R&D and Prototyping Microfabrication Services

Lithography

| Tools | Type | Resolution/Alignment | Sample Size |

|---|---|---|---|

| Heidelberg DWL 66+ Low-Res Writehead | Laser Writer | 1.5 μm / ±0.5 μm | Chip - 8" Wafers |

| Heidelberg DWL 66+ High-Res Writehead | Laser Writer | 400 nm / ±0.5 μm | Chip |

| Heidelberg DWL 66+ 5" Masks Writer | Laser Writer | 2 μm / ±0.5 μm | Silica/Cr 5" Mask |

| EVG 610 | Mask Aligner | 2 μm / ±1 μm | Chip - 4" Wafers |

| Quintel 4000 | Mask Aligner | 3 μm / ±2 μm | Chip - 4" Wafers |

Deposition

| Tools | Type | Targets/Gases | Sample Size |

|---|---|---|---|

| CLUSTERLINE® 200 Co-Sputtering Chamber | Sputtering/Reactive sputtering | Ti, Pt, Al, Sc, Mo | Chip - 8" Wafer |

| CLUSTERLINE® 200 Single Target Chamber | Sputtering/Reactive sputtering | Al, Sc20, Sc30, Sc40 | Chip - 8" Wafer |

| AJA ATC Sputtering System | Sputtering | Ti, Al, Pt, FeGa, Si, SiO2, B | Chip - 8" Wafer |

| Plasma-Therm HDP-CVD | CVD | SiH4, PH3, B2H6, Ar, GeH4, O2, He, CH4, H2, N2 | Chip - 8" Wafer |

Etching

| Tools | Type | Gases | Sample Size |

|---|---|---|---|

| ULVAC NLD-570 | Deep Oxide Etcher | Ar, C4F8, CHF3, Cl2, NF3, O2 | Chip - 6" Wafers |

| Plasma-Therm ALE | ALE | BCl3, CF4, CH4, CHF3, Cl2, H2, HBr, N2, O2, SF6 | Chip - 8" Wafers |

| Oxford PlasmaLab100 | ICP RIE | Ar, BCl3, Cl2, O2 | Chip - 6" Wafers |

| Plasma-Therm 790 | RIE | Ar, CHF3, O2, SF6 | Chip - 6" Wafers |

| Pie Scientific Tergeo Pro | Plasma Asher | Ar, CHF3, O2, Water Vapor | Chip - 6" Wafers |

Metrology & Characterization

| Tool | Type | Sample Size |

|---|---|---|

| Supra 25 SEM | Electron Microscopy | Chip - 4" Wafers |

| KLA - TENCOR FLX | Residual Stress | Chip - 8" Wafers |

| Woollam ESM- 300 | Ellipsometer | Chip - 8" Wafers |

| PANalytical/Philips X'Pert Pro | XRD | Chip - 4" Wafers |

| Aixacct AixDBLI | Piezoelectric Characterization (d33, d31) | Chip - 8" Wafers |

Consulting Services

Foundry Transition

Partner with us to seamlessly transition your devices from R&D to volume production. We will help you with:

- Foundry selection

- Process design & compatibility review

- Ongoing production support

Design and Analysis Automation

Streamline your MEMS development with our advanced automation tools and custom design solutions:

- Custom piezoelectric MEMS design and optimization

- Generative layout and DRC tools

- FEM integration & automation